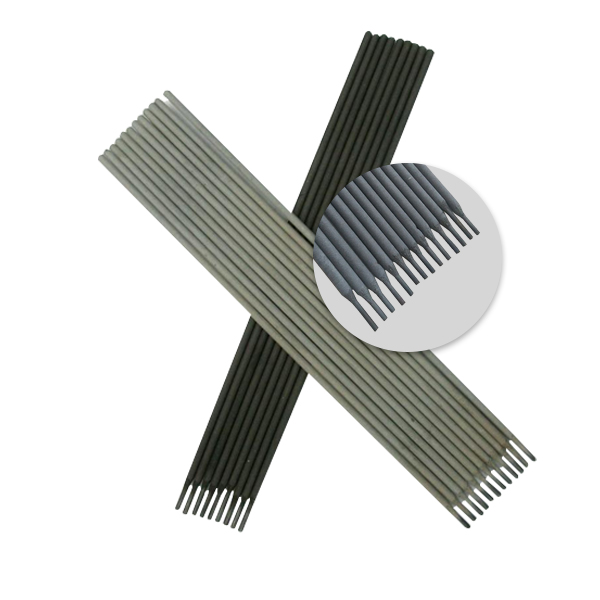

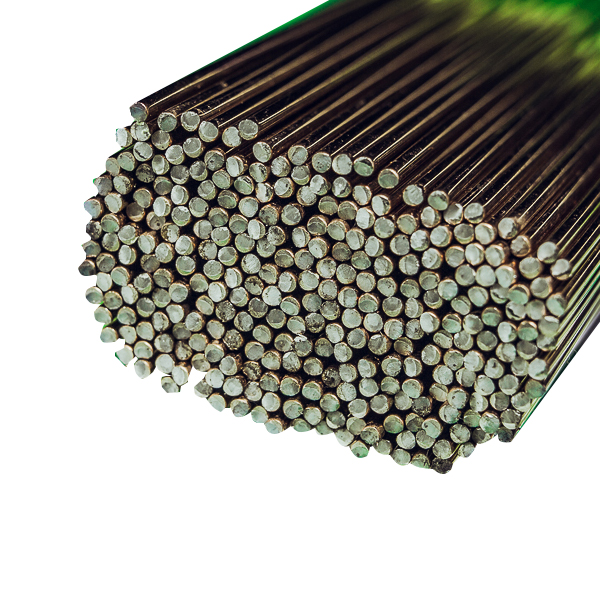

baja Karbon tinggi Manual éléktroda E9818-G Soldering makings

KOMPONEN KIMIA:

| PADUNGAN (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| ATURAN GB/T | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| ATURAN AWS | - | - | - | - | - | - | - | - | - | - |

| NILAI CONTOH | 0,050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0,005 | 0.004 | 0.018 | 0.004 |

SIFAT MEKANIKAL:

| HARTA | Kakuatan ngahasilkeun (MPa) | Kakuatan éksténsif (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGATION(%) | |||||

| ATURAN GB/T | - | - | - | - | - | |||||

| ATURAN AWS | - | - | - | - | - | |||||

| NILAI CONTOH | 915 | 992 | - | 65/-20 | 16 | |||||

Parameter las anu disarankeun:

| SPESIFIKASI DIAMETER (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| LISTRIK (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

980Mpa kakuatan super tinggi low ferrohidrogen bubuk tipe low éléktroda baja alloy.

arc stabil, Santika leutik, panyabutan slag alus

Alus kinerja las sadaya-posisi, alus kateguhan suhu low, résistansi retakan sarta kateguhan dampak suhu low.

KOMPONEN KIMIA:

| PADUNGAN (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| ATURAN GB/T | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| ATURAN AWS | - | - | - | - | - | - | - | - | - | - |

| NILAI CONTOH | 0,050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0,005 | 0.004 | 0.018 | 0.004 |

SIFAT MEKANIKAL:

| HARTA | Kakuatan ngahasilkeun (MPa) | Kakuatan éksténsif (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGATION(%) | |||||

| ATURAN GB/T | - | - | - | - | - | |||||

| ATURAN AWS | - | - | - | - | - | |||||

| NILAI CONTOH | 915 | 992 | - | 65/-20 | 16 | |||||

Parameter las anu disarankeun:

| SPESIFIKASI DIAMETER (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| LISTRIK (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Tulis pesen anjeun di dieu sareng kirimkeun ka kami